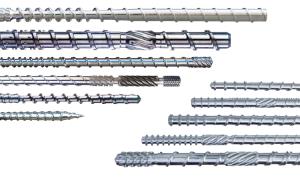

Screw and barrel for extruder

MaterialHigh quality alloy-steel

1) 38CrMoAlA(JIS SACM645)

2) 42CrMo(JIS SCM440)

3) 9 Cr18MoV

4) SKD11

5) C276

6) GH113

Heat-treatment

Nitriding treatment

Electroplated hard-chrome finish

Medium-high frequency quenchingSpray bimetallic coatingVacuum quenchingApplications

1) For plastic product extrusion:Blow film, sheet, plate, pipe extrusion

2) For chemical fiber extrusion:PET , PA6 , film, non-woven fabric,rope fiber

3) For plastic recycling and pelletizing

4) For cable extrusion: PVC, PE, PBT and rubber fluoride